Manufacturing ERP software

Get rid of old tools and use the cloud to manage manufacturing.

Complete control of the production process

Combine production space planning and production with a manufacturing management system that makes real-time coordination across all business segments such as customer management, sales orders, warehouse, purchasing, accounts, and financial reporting, easier. A modern manufacturing management system simplifies the production cycle, helps track material consumption, and review capacity planning, handle subcontracting, and more.

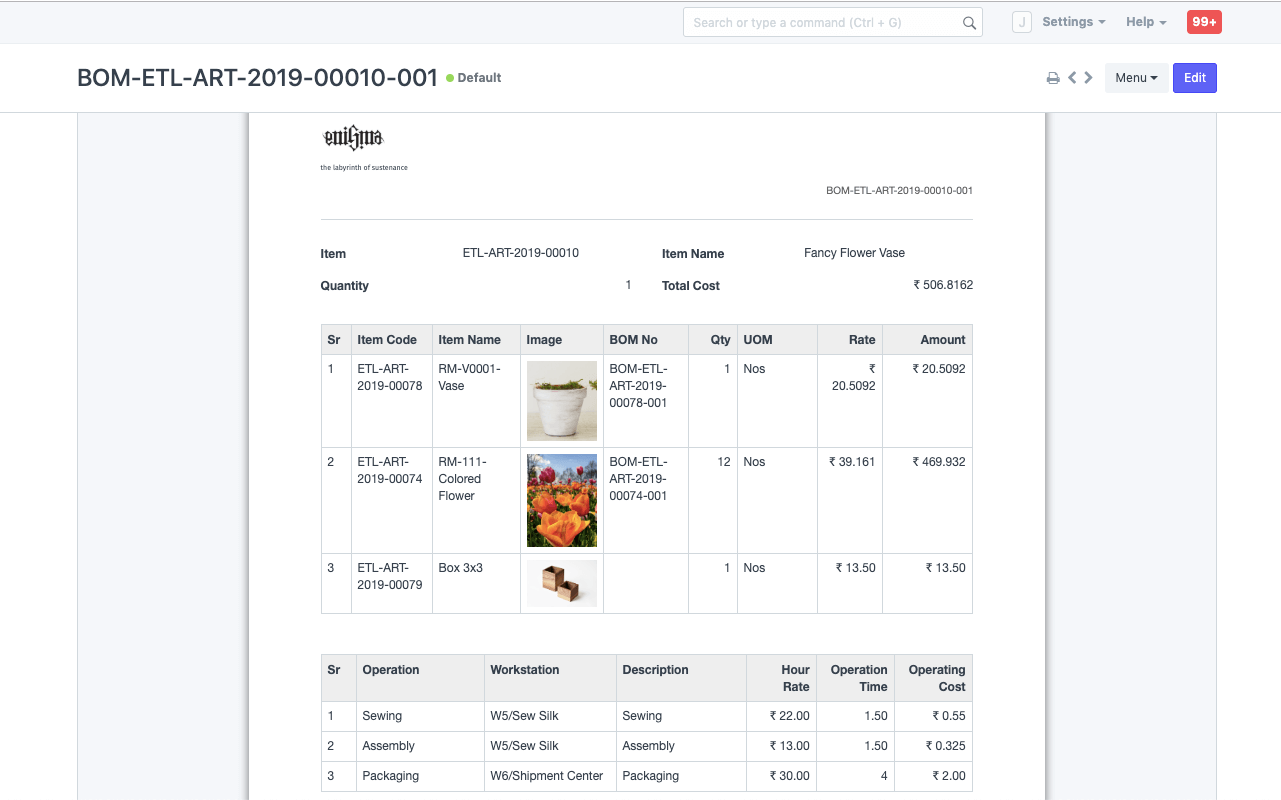

Invoicing of materials (BOM)

Invoicing of materials is the heart of any cloud manufacturing management system, so having a well-defined Invoicing of materials enhances robustness and accuracy. The system presents the Invoicing of Materials in a hierarchical form with the final product on top. It also contains product codes, parts specifications, quantities, costs and any other details.

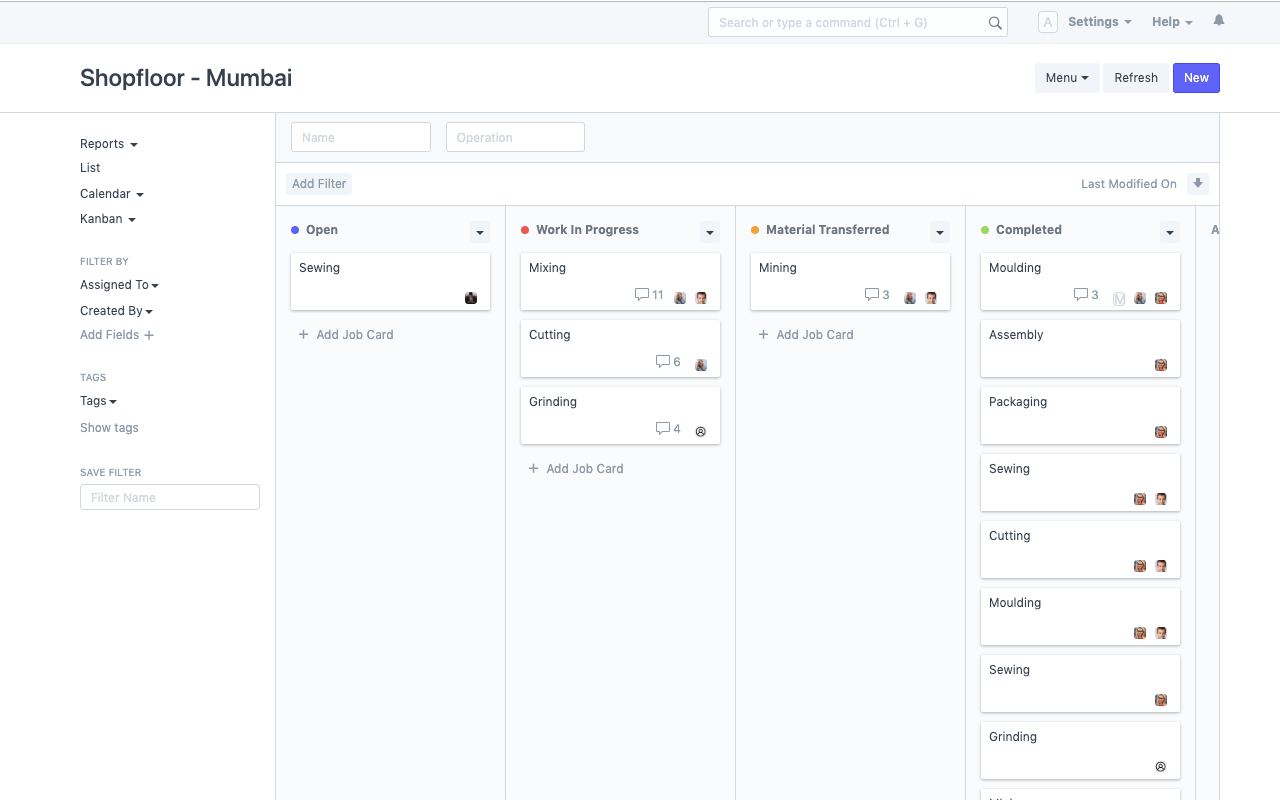

Production space management

You can automatically distribute daily activities among workers through job cards, operation characteristics and work units on the system. View the status of work done for manufacturing products in real time, the location of all work units, employee tasks, status of each work order and remaining steps, all on one screen.

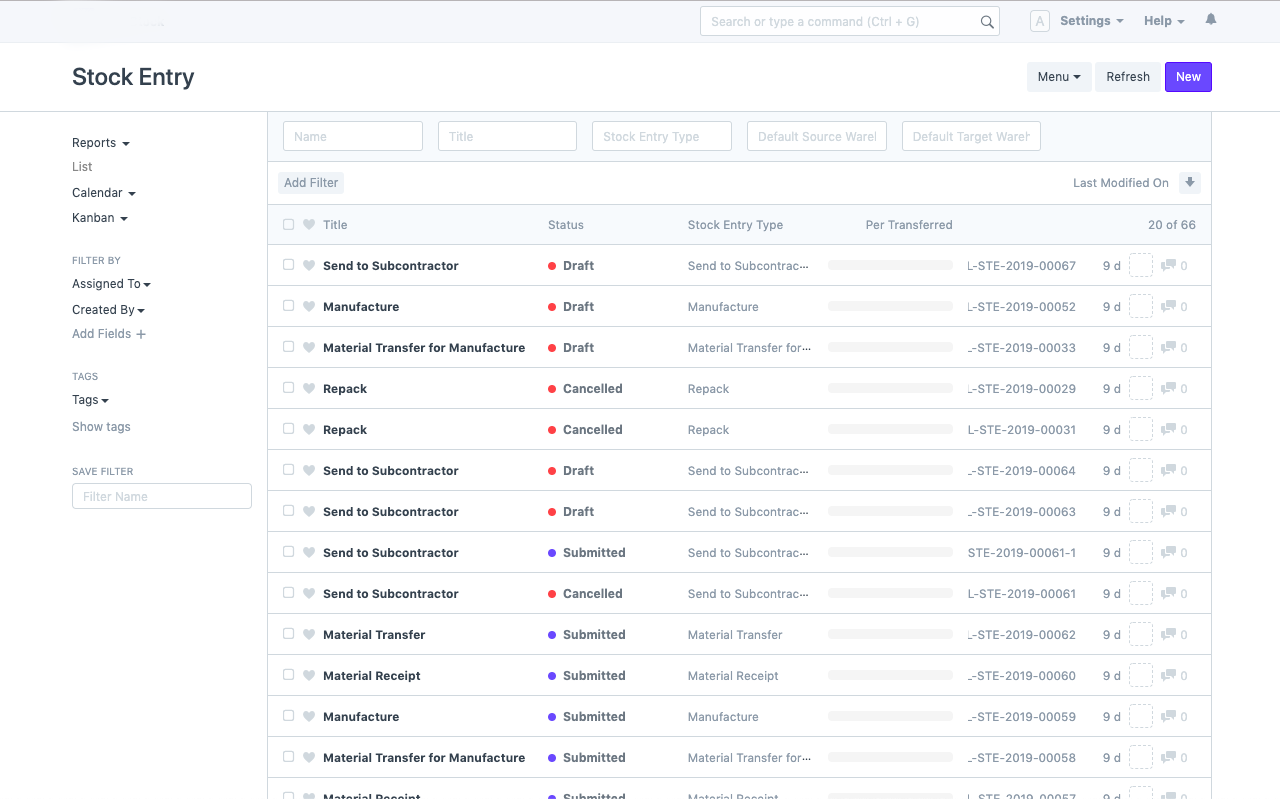

Subcontracting

If your work includes outsourcing operations with a supplier, you should try the Subcontracting feature on the manufacturing management system, as the system is based on facilitating the supply of raw materials and following up on the supplier's employment and operations. The final product cost is calculated based on the cost of raw materials and services purchased.

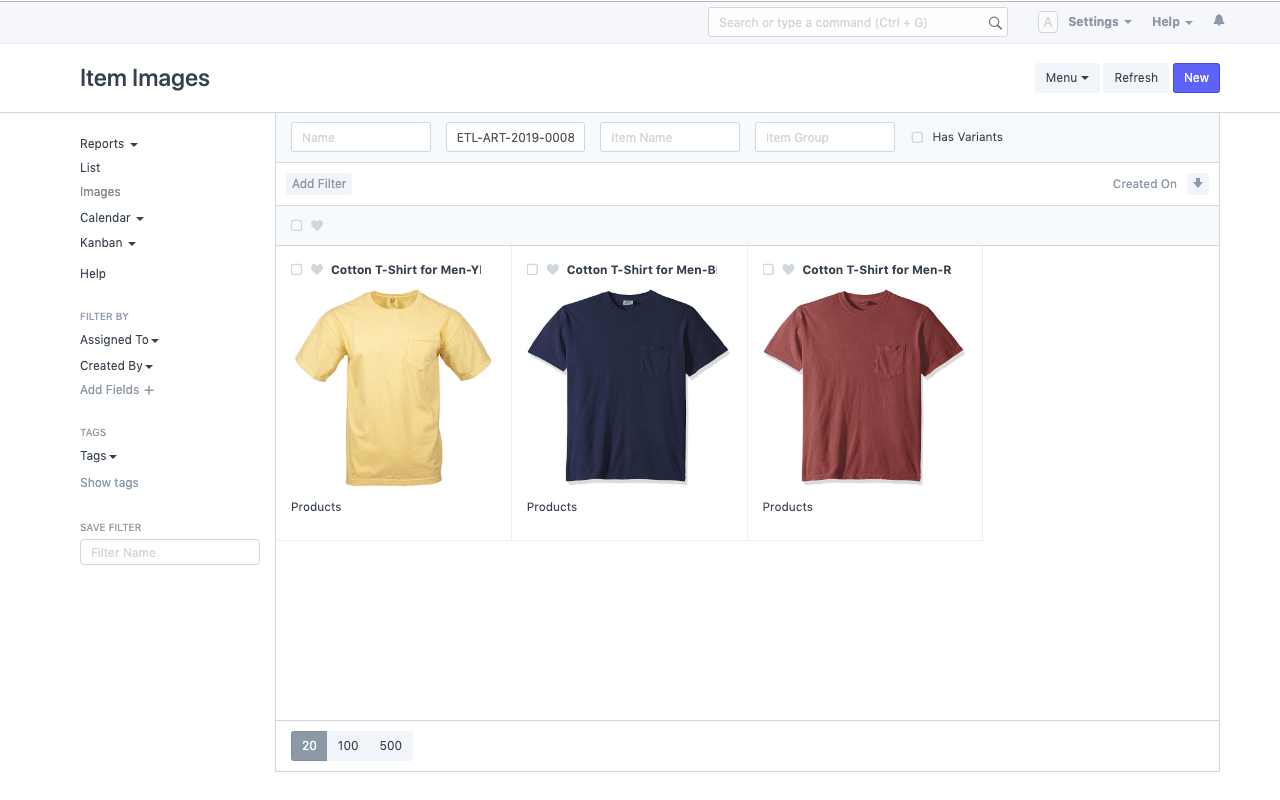

commodity substitutes

Suppose you produce T-shirts in different colors and sizes, then you have to track each type and its alternatives in what is known as commodity alternatives. The basic good is recorded in the form of a model and the rest of the diversifications are recorded in the form of its substitutes. You can record the characteristics of each commodity of color and shape as an alternative.

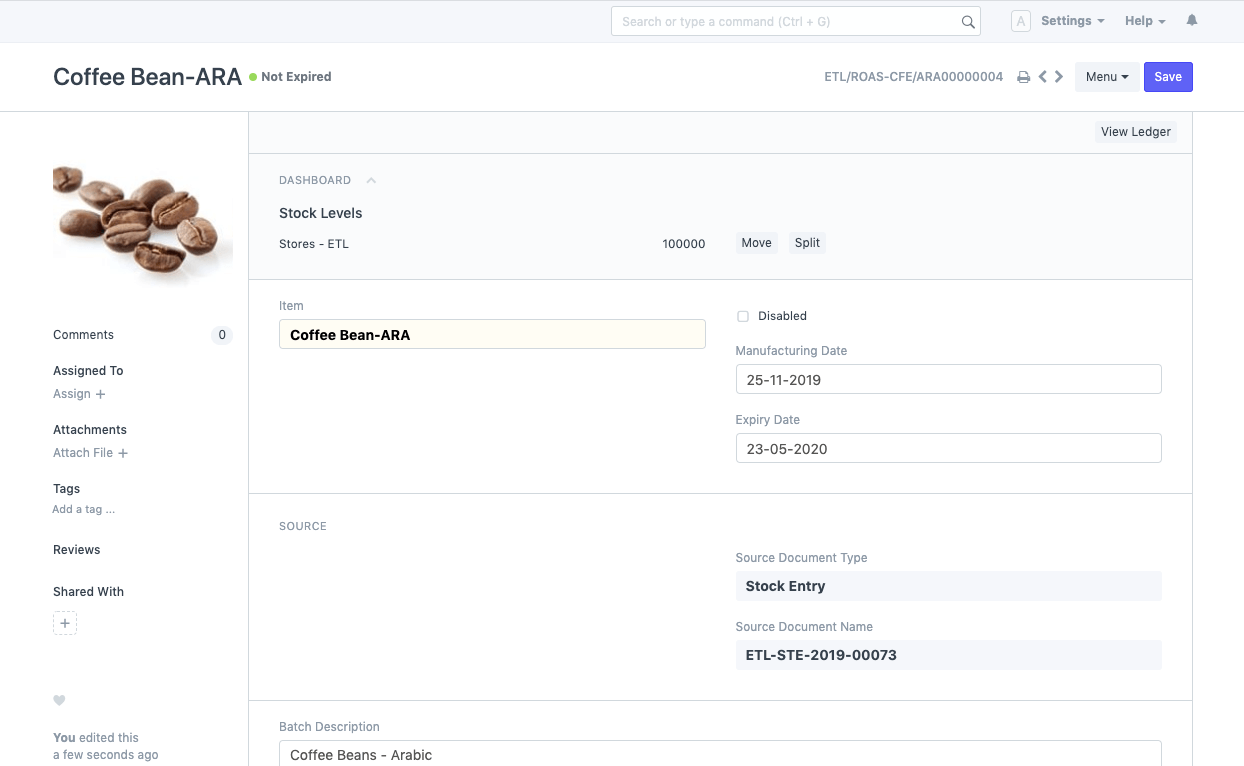

Inventory compilation

Collected goods can be easily managed using the integrated inventory management system. The system enables you to know the availability of the product in real time while keeping the manufacturing dates, validity and other details. You can also scan merchandise barcodes to quickly search for items in inventory to make data-driven decisions.

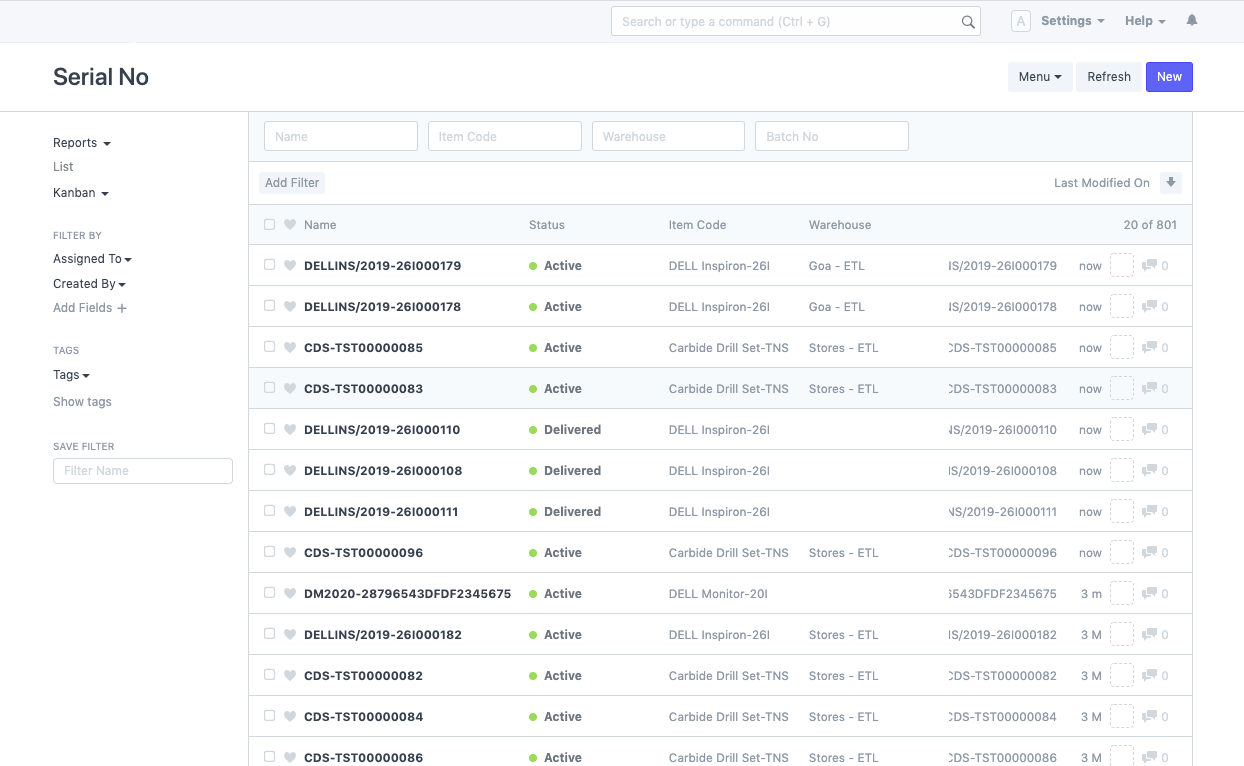

serial stock

Use serial numbers to uniquely identify items, just set up the label series and the system will automatically work on the serial numbers for new stock. You can also scan merchandise barcodes to quickly search for them in stock.

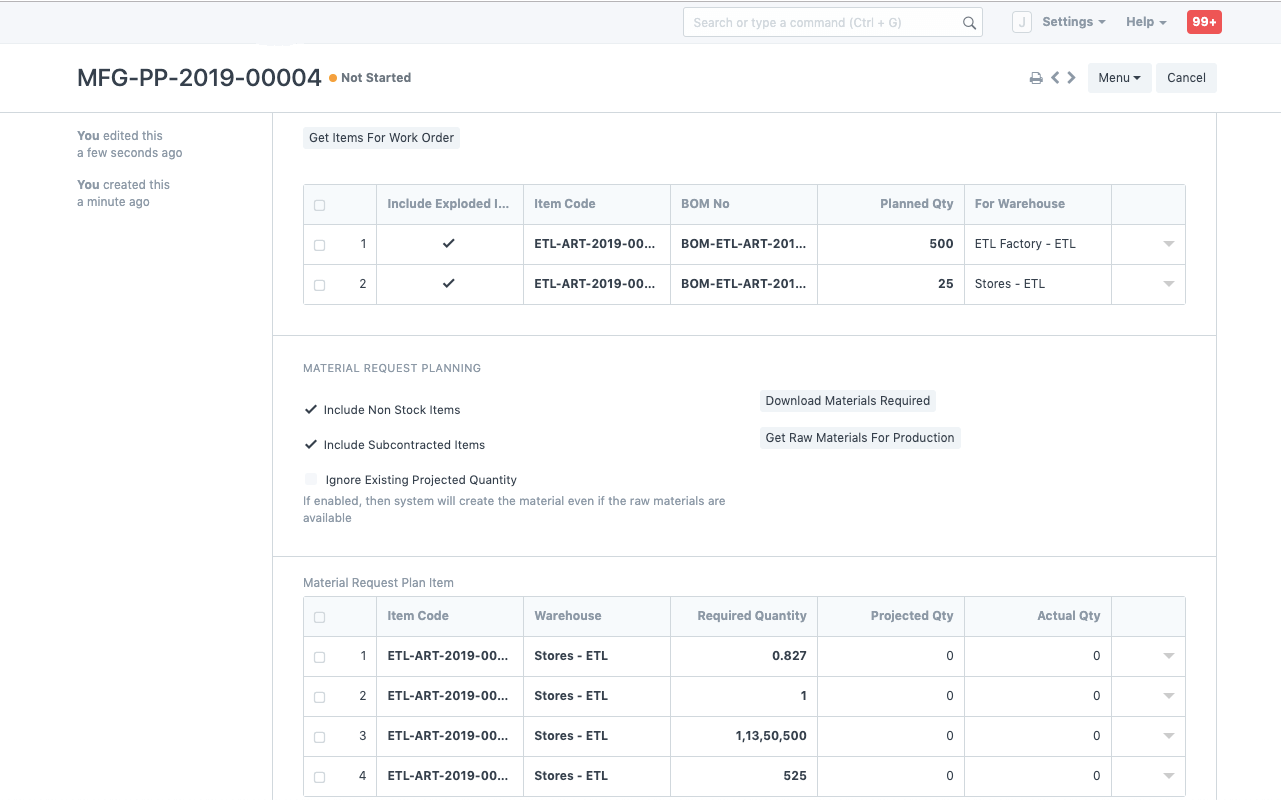

Material resource planning

Whether it is a work order against a sales order or a material request, the system will display all aspects of your resource planning. Track material consumption for serial or batch items to reduce costs and achieve zero wasted resources.

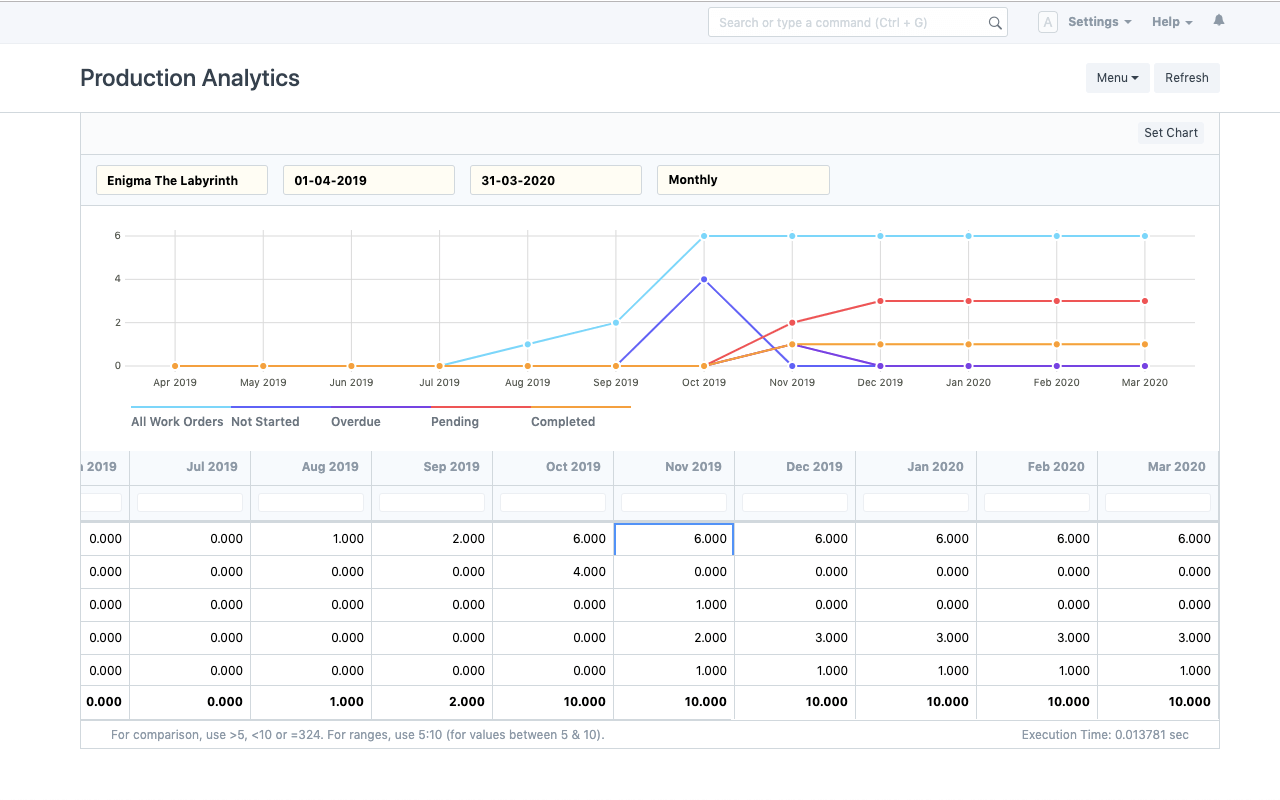

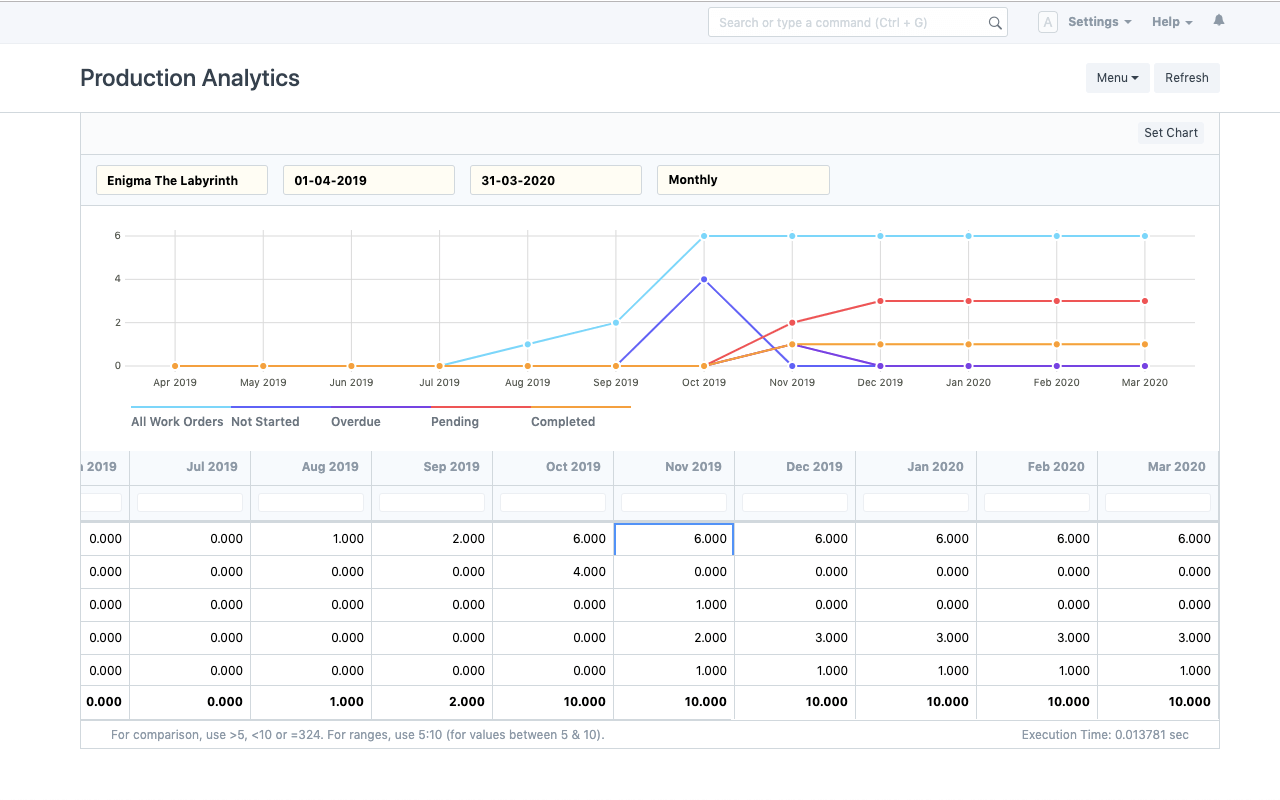

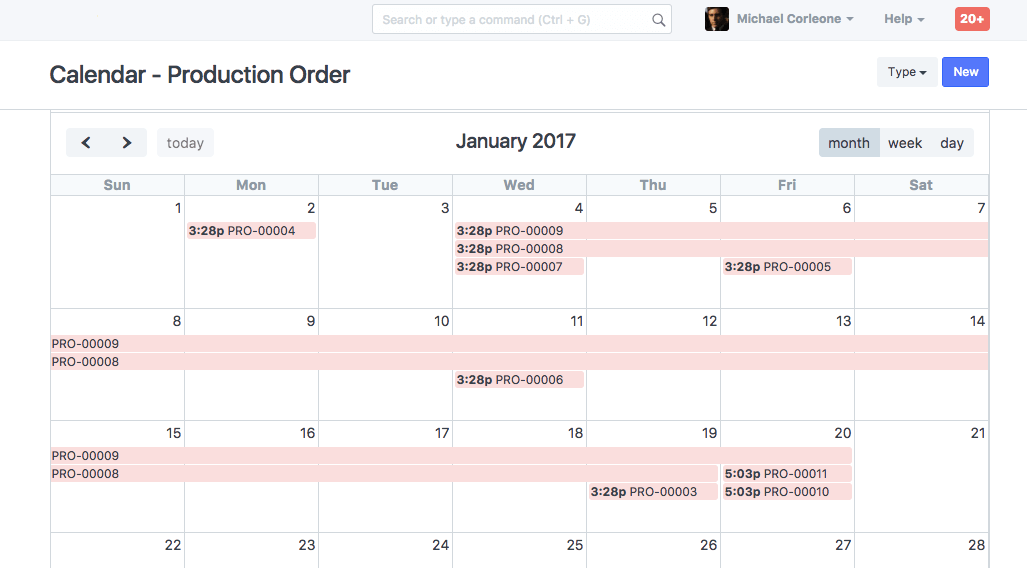

capacity planning

Optimize work platforms based on available resources for open production orders. Detect and overcome bottlenecks in production by creating capacity diagrams. You can also keep planning schedules for a predetermined period of time (30 days, 45 days, etc.).

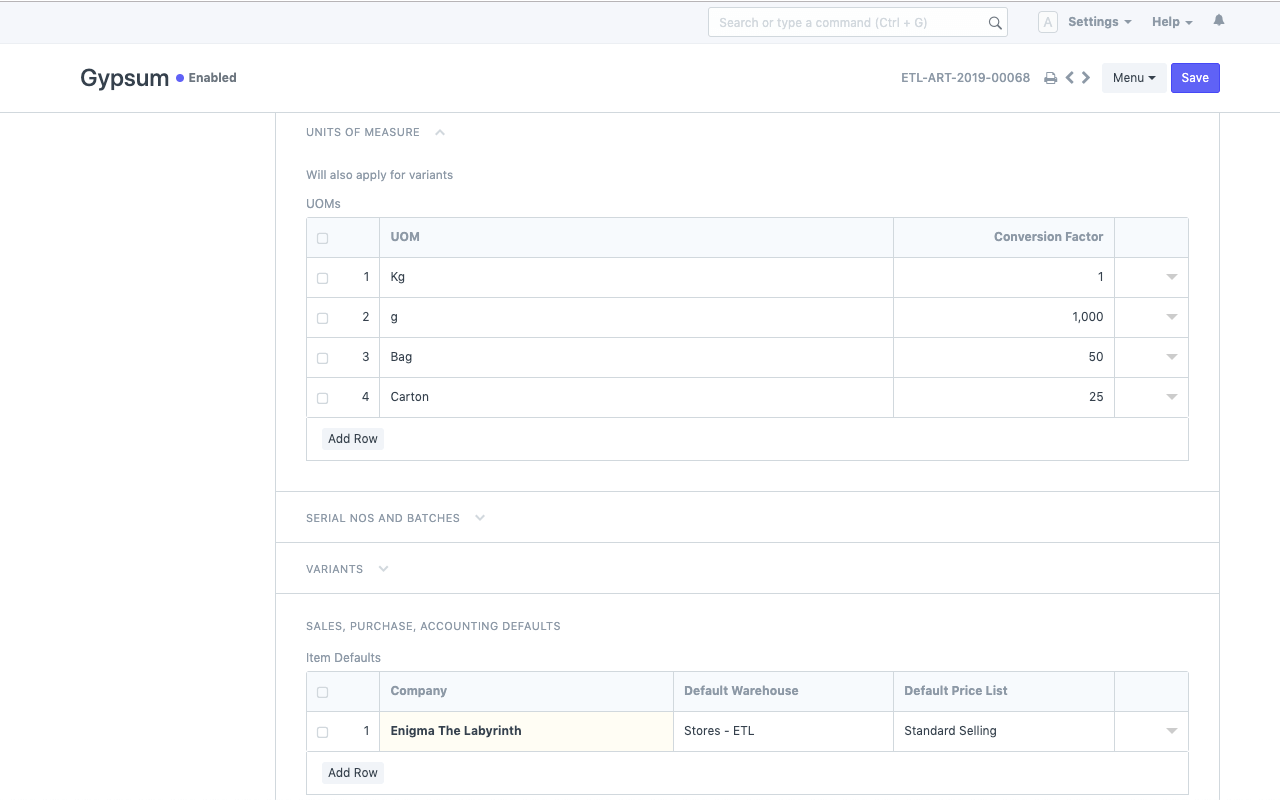

Measure in multiple units

Don't let systems get in the way of measuring materials the way you want, track multiple units of your inventory. Set up conversion factors in the main commodity, facilitate buying and selling and stock transactions, and let the system do all the conversion!

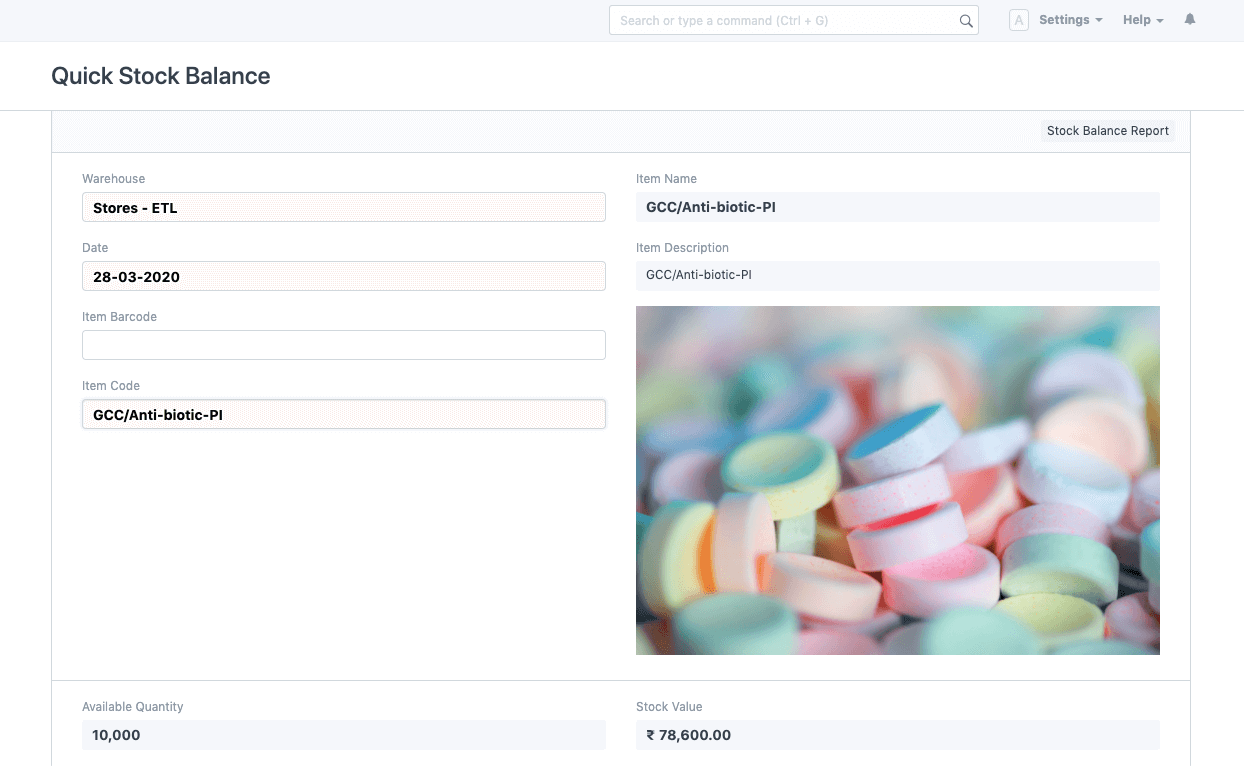

Quickly check stock levels

You can perform inventory checks to match the amount of physical inventory in stores and the inventory registered on the system. Just scan the barcode through any device (no barcode scanner needed) and start calculating.

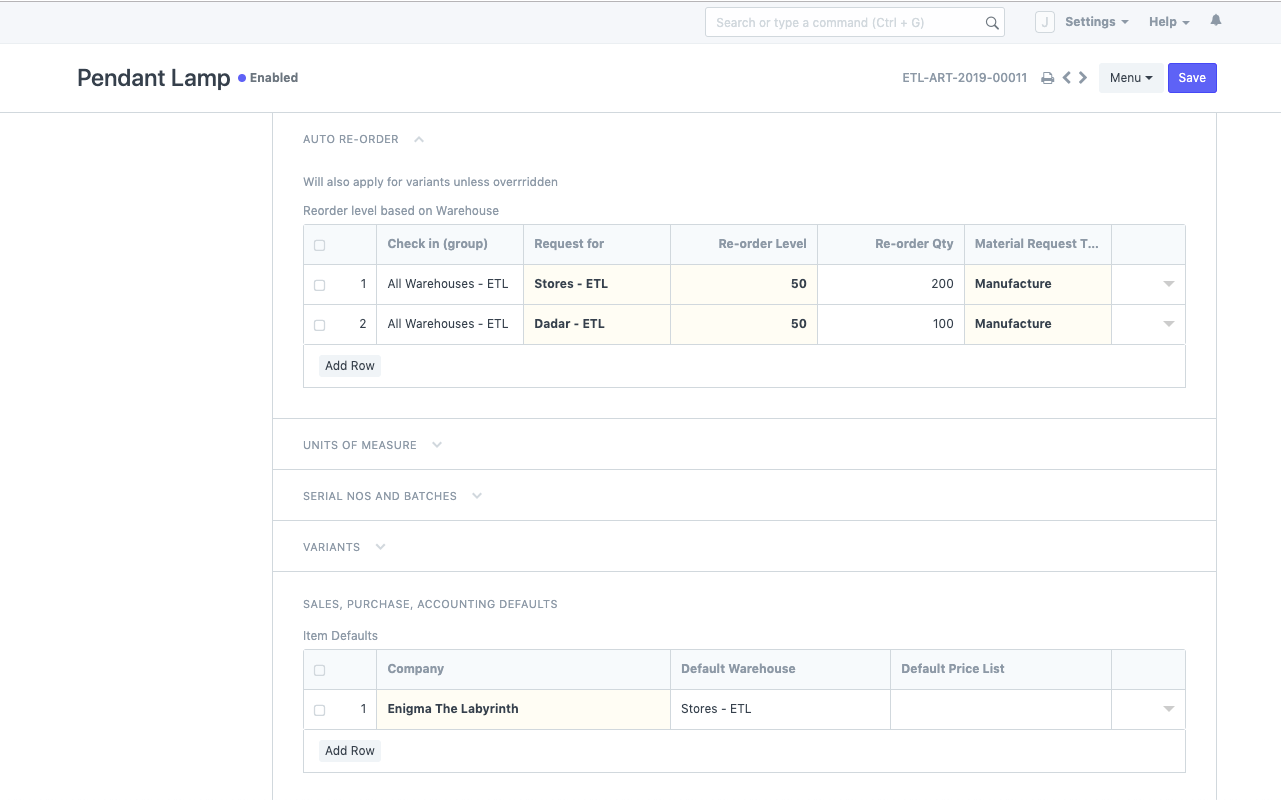

Automatic stock replenishment

To prevent stockouts, keep track of the level of demand for the item, and when the stock reaches this level, the program will automatically create a request for this item. This helps you replenish stock at exactly the right time and reduce the chances of stock exhaustion.

Quick customizations

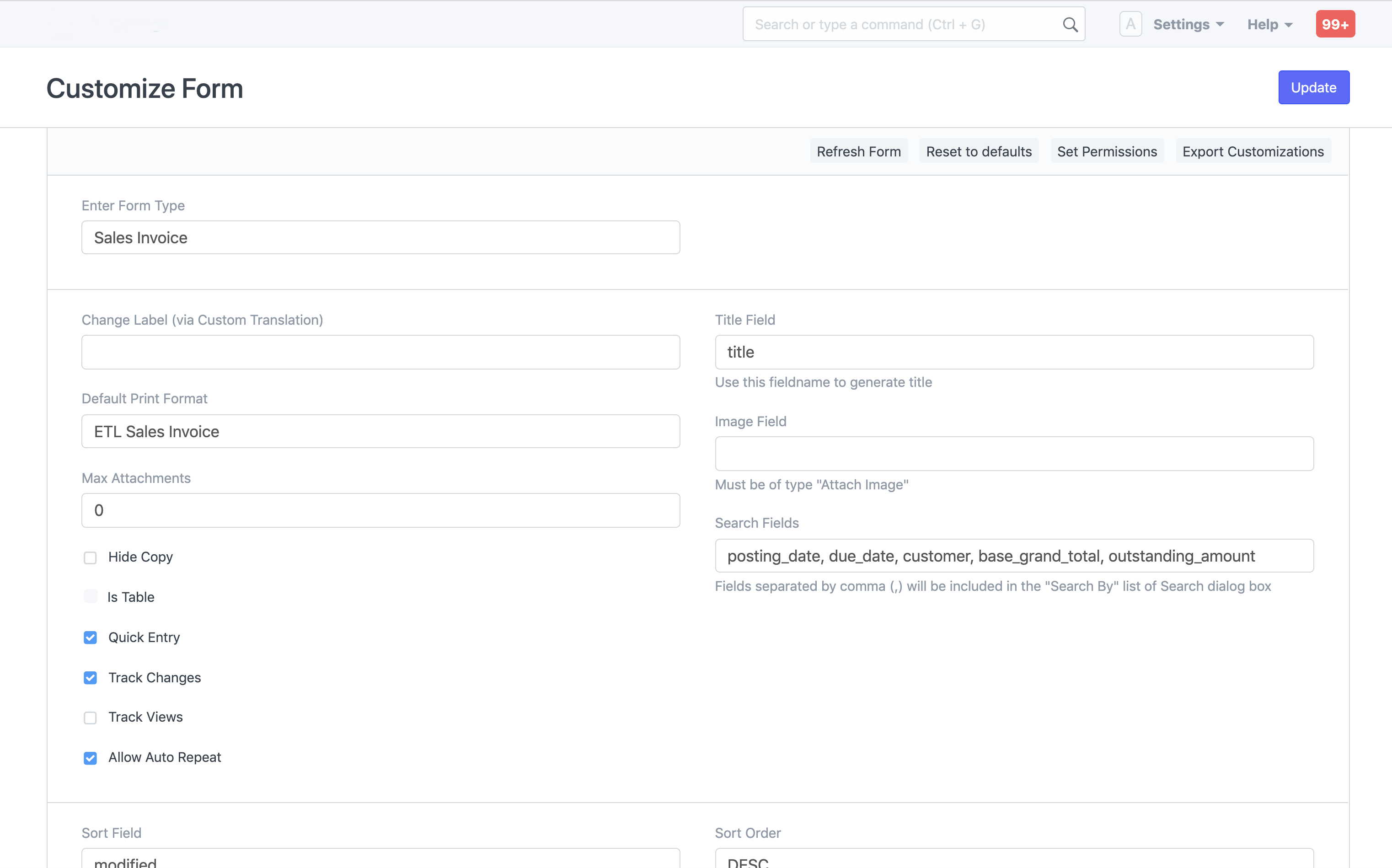

Create your own manufacturing management system, map your most important data by adjusting custom fields on forms. Customize behavior patterns with auto-fetching values, hide fields based on user role, and create custom print patterns without writing any line of code.

Merge with your favorite apps

MhamCloud systems are characterized by providing the latest solutions to create a state of communication between MhamCloud systems and other applications.